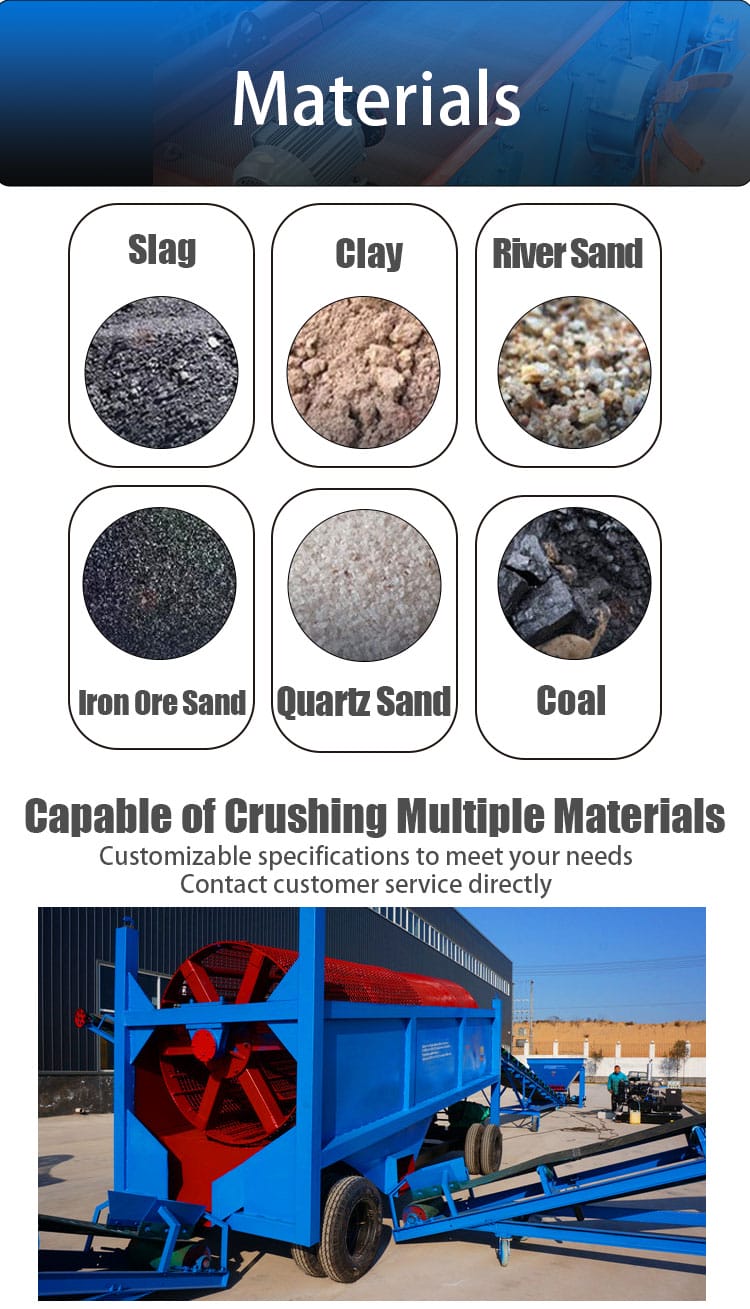

Applicable materials:Coal gangue, shale, slag, cinder, coal, stone, bentonite, iron ore, bluestone, mountain stone, water slag, limestone, weathered sand, diabase, granite

Application scope: Coal, sand field, stone field, chemical industry

The trommel screen machine enhances material screening by preventing screen clogging, especially with wet materials. It ensures higher output and system reliability. This machine handles materials of all properties, including coal, coke, and slaked lime. Huashengming Heavy Industry provides customizable options for screen materials and hole sizes, offering high efficiency, durability, and minimal maintenance.

The motor powers the Trommel screen machine device through a coupling and reducer, rotating it around its axis. Materials inside the drum flip and roll due to the drum’s inclination and rotation. Qualified materials pass through the outer screen, while the rest exit through the drum’s end. The rolling motion prevents clogging by ejecting trapped particles.

1、Affordable and profitable: Low investment with quick returns—recover costs in a month.

2、Labor-saving: Automates sand screening, reducing manual effort.

3、Optimal sand yield: Delivers 100% usable sand compared to manual screening.

4、Moisture handling: Screens wet sand efficiently without clogging.

5、High speed: Screens up to 18 tons per hour, far surpassing manual methods.

6、User-friendly design: Compact, lightweight, and easy to move, ideal for any site.

The drum screen effectively prevents screen clogging when screening wet materials. It increases the output and reliability of the screening system. This machine suits various materials, including wet and easy-to-block materials like coal, coal gangue, coke, and slaked lime. Choose the right drum screen based on your material’s properties. Huashengming Heavy Industry customizes screen materials and hole sizes to meet your requirements. The machine ensures high screening efficiency, a long lifespan, and low maintenance costs.

| Model | Drum specifications (m) | Drum angle | Revolution (r/min) | Sieve Pore Size | Feeding size (mm) | Capacity(m3/h) | Motor power (kw) | |

| Screen size (2mm) | Screen size (20m) | |||||||

| GTS820 | Φ0.8X2 | 6° | 32 | 2-20 | Mesh size*2.5 | 8 | 30 | 3 |

| GTS830 | Φ0.8X3 | 6° | 32 | 2-20 | Mesh size*2.5 | 10 | 50 | 3 |

| GTS1030 | Φ1X3 | 6° | 25 | 2-20 | Mesh size*2.5 | 12 | 60 | 4 |

| GTS1040 | Φ1X4 | 6° | 25 | 2-20 | Mesh size*2.5 | 15 | 80 | 4 |

| GTS1230 | Φ1.2X3 | 6° | 20 | 2-20 | Mesh size*2.5 | 16 | 100 | 5.5 |

| GTS1240 | Φ1.2X4 | 6° | 20 | 2-20 | Mesh size*2.5 | 18 | 120 | 5.5 |

| GTS1250 | Φ1.2X5 | 6° | 20 | 2-20 | Mesh size*2.5 | 20 | 140 | 5.5 |

| GTS1530 | Φ1.5X3 | 6° | 17 | 2-20 | Mesh size*2.5 | 20 | 120 | 5.5 |

| GTS1540 | Φ1.5X4 | 6° | 17 | 2-20 | Mesh size*2.5 | 22 | 150 | 7.5 |

| GTS1550 | Φ1.5X5 | 6° | 17 | 2-20 | Mesh size*2.5 | 25 | 180 | 11 |

+86-18703839693

+86-18703839693