In the mining industry, efficiency and reliability are paramount for maintaining competitive advantage. To meet rising demand and processing requirements, companies are increasingly turning to advanced crushing technologies. In this case study, we will explore how implementing a Twin Tooth Roll Crusher (TTRC) significantly improved the ore processing efficiency of a mining company.

Background

A mining company specializing in ore extraction and processing had been using conventional crushers for several years. As the volume of raw ore increased, they encountered issues such as reduced throughput, excessive energy consumption, and frequent maintenance breakdowns. Seeking an efficient solution, they turned to the twin tooth roller crusher.

Challenges

The older equipment was no longer able to meet the growing demands of the operation. Production capacity was suboptimal, energy use was high, and frequent machine downtimes led to lost revenue. The company needed a solution that could enhance throughput and reduce energy consumption while lowering overall maintenance costs.

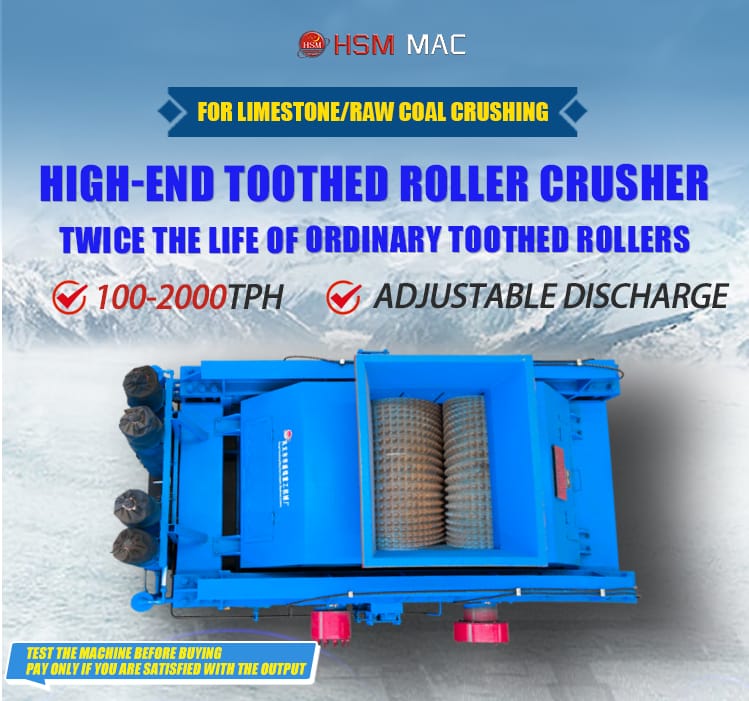

Solution: Twin Tooth Roll Crusher

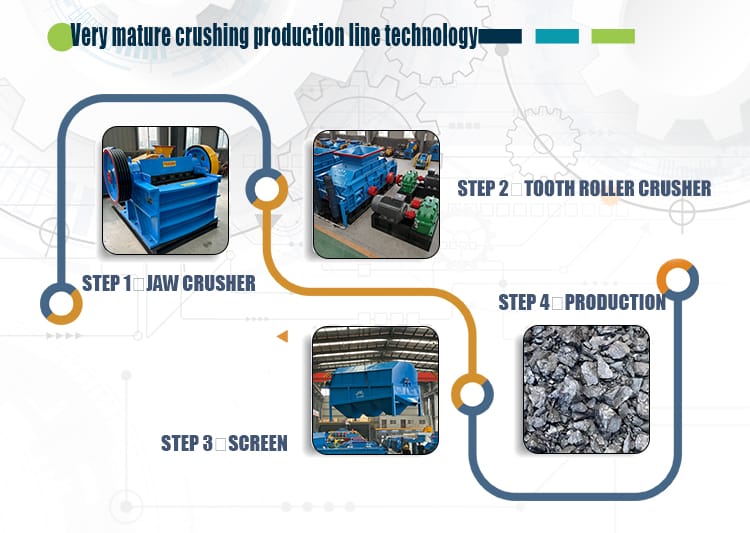

After evaluating the company’s needs and production challenges, we recommended the Twin Tooth Roller Crusher. Below are the primary benefits this machine brought to the operation:

- Increased Throughput: The dual-tooth roll design ensures a more efficient crushing process, allowing the company to handle higher volumes of ore with improved throughput.

- Energy Savings: The crusher operates with reduced energy consumption compared to traditional crushers, leading to lower operational costs.

- Durable and Low Maintenance: With its robust design and simple mechanics, the twin tooth roll crusher requires minimal maintenance, reducing downtime and increasing production reliability.

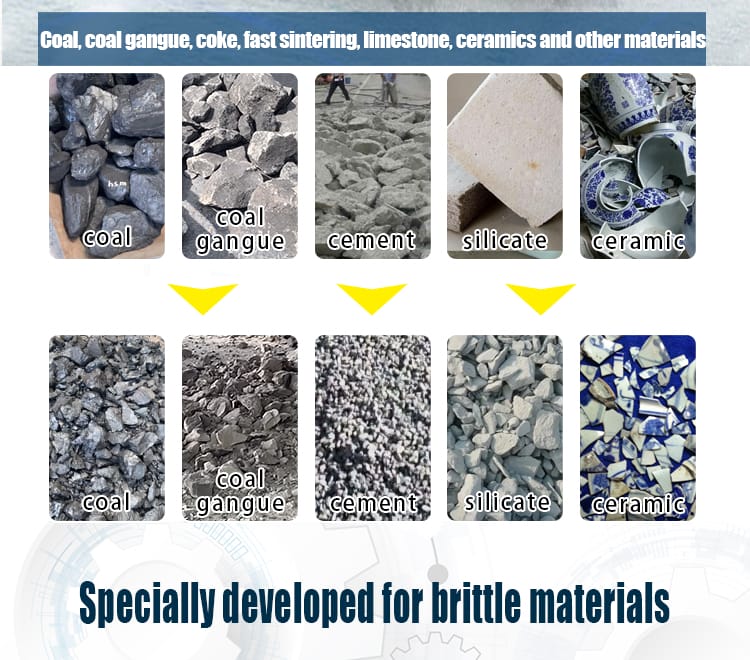

- Adaptability to Various Materials: From hard ores to softer materials, the twin tooth roll crusher handles a wide range of feedstock with ease, ensuring consistent and high-quality output.

Results: Enhanced Production Efficiency

The results were immediately apparent. The mining company reported a 25% increase in ore processing efficiency, alongside a 10% reduction in energy consumption. Furthermore, machine downtime was significantly reduced, leading to smoother, uninterrupted operations.

Customer Feedback

The company’s management praised the performance of the twin tooth roller crusher, noting how it addressed their production bottlenecks and reduced overall operational costs. The improved reliability and adaptability of the equipment made a significant difference in their ability to meet customer demands and improve profitability.

Conclusion

This case study demonstrates the value of investing in advanced crushing equipment to enhance ore processing efficiency. The Twin Tooth Roll Crusher offers an ideal solution for mining operations looking to increase production capacity, reduce energy consumption, and minimize downtime.

If you’re experiencing similar challenges in your mining operation, a twin tooth roll crusher may be the solution you need. Contact us today to learn how our crushers can help optimize your production process.