In modern industrial production, material crushing is a critical step in many processing workflows. As an efficient crushing device, the impact crusher plays a significant role across various fields.

The Function of Impact Crusher

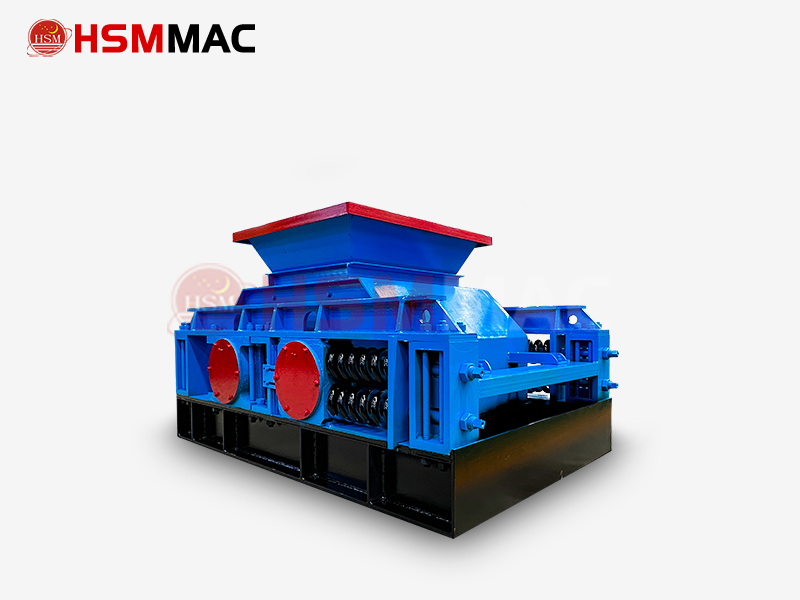

An impact crusher, operates on the principle of a high-speed rotating rotor applying tremendous impact force to the material entering the crushing chamber. Once fed into the machine. The material is struck by rapidly rotating hammers or blow bars. Thereby being crushed into smaller particles. This method of crushing not only effectively processes materials with higher hardness. Such as granite and basalt, but it also features advantages like uniform product particle size and good particle shape.

Typically, the design of this equipment includes adjustable gap settings, allowing operators to adjust the output particle size according to requirements, ensuring that the product meets specific application needs. Moreover, it comes equipped with wear-resistant components to extend service life and reduce maintenance frequency. The equipment also boasts a compact structural design, occupying minimal space and facilitating installation and mobility, making it very suitable for working environments with limited space.

With advancements in technology, new models of impact crushers continue to emerge. They integrate intelligent control systems that can achieve automated operation and monitoring, further enhancing production efficiency and safety. Whether in mining operations, construction waste recycling, or the cement manufacturing industry, this equipment provides users with a reliable crushing solution.