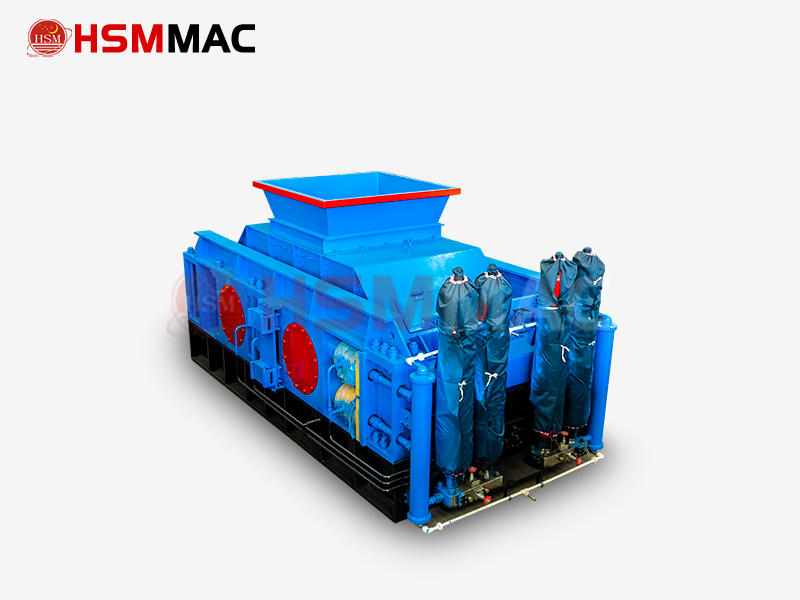

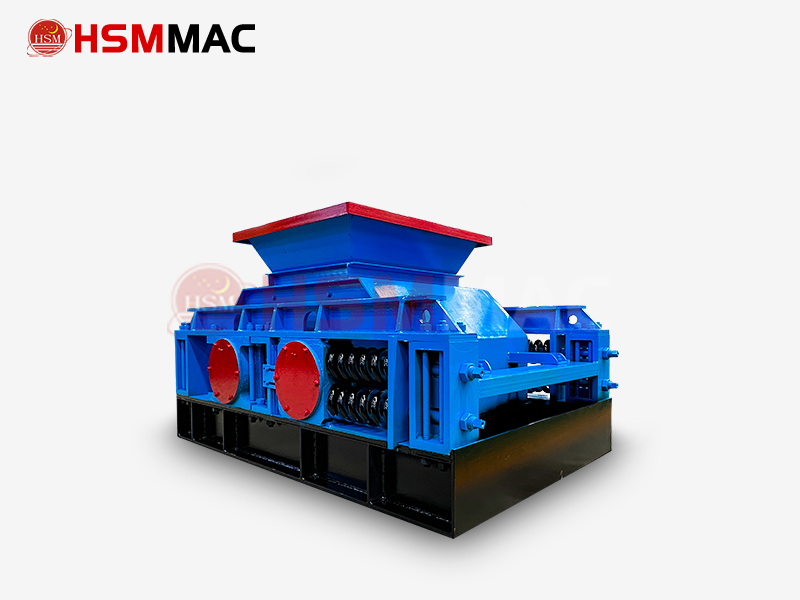

In industries such as mining, building materials, and chemicals. Large double roll crushers have become the core equipment for crushing operations due to their unique advantages. These advantages are manifested in the following three aspects: Large Double Roll Crusher: An Efficient and Energy-saving Crushing Tool I. Efficient Crushing with Leading Production Capacity The large double roll crusher employs a design of dual rolls rotating in opposite directions. Achieving efficient crushing of materials through powerful extrusion forces. Its large-diameter rolls, matched with high-power motors, can handle large blocks of materials (such as limestone and iron ore). With a daily processing capacity of up to several thousand tons per single unit, meeting the demands of large-scale production. II. Precise Particle Size Control with Customizable Output By adjusting the gap between the two rolls, the discharge particle size (ranging from 0.5 to 50 mm) can be precisely controlled, resulting in uniformly shaped finished products with a low over-grinding rate. This feature is particularly crucial in the production of sand and gravel aggregates, effectively enhancing concrete strength and reducing the cost of gradation adjustment. III. Wear-resistant, Durable, and Easy to Maintain The roll surfaces are made of high-manganese steel or composite wear-resistant materials. Extending their service life…

As a crucial piece of equipment in industries such as mining, building materials, and chemical engineering. The double toothed roller crusher holds a pivotal position in the crushing field due to its unique advantages. Its core strengths are manifested in the following three aspects: Double Toothed Roller Crusher: An Efficient and Energy-Saving Crushing Tool I. Efficient Crushing with Precisely Controllable Particle Size The double toothed roller crusher employs a design where two rollers rotate towards each other, achieving efficient material crushing through the shearing. And squeezing actions of the toothed roller surfaces. The tooth configuration can be customized according to material characteristics, enabling it to handle both hard ores and sticky, wet materials. Moreover, the particle size of the output can be precisely controlled by adjusting the roller gap, meeting various process requirements, minimizing over-crushing. And enhancing the quality of the finished products. II. Energy-Saving and Environmentally Friendly, with Low Operating Costs Compared to traditional crushing equipment, the double toothed roller crusher adopts a low-speed, high-torque design, reducing energy consumption by over 30%. Its sealed structure effectively prevents dust from escaping, and when combined with noise reduction devices, it enables green production. Additionally, the roller surfaces are made of wear-resistant…

As a core piece of equipment in industries such as mining and building materials. the double-stage crusher has become a powerhouse in the field of hard material crushing, thanks to its unique technological advantages. Its key strengths are reflected in the following three aspects: Double Stage Crusher: An Efficient and Energy-Saving Crushing Tool I. Efficient Crushing, Doubled Production Capacity The double-stage crusher employs a tandem design with upper and lower rotors. After undergoing primary coarse crushing, materials directly enter the secondary fine crushing stage. creating a continuous operation mode of “single feeding, double crushing.” Compared to traditional single-stage crushers, the crushing ratio is increased by over 50%. A single unit of this equipment can achieve fine processing from raw materials to finished products, making it particularly suitable for large-scale processing of medium- to high-hardness materials such as coal gangue and limestone, with daily production capacities reaching up to the thousand-ton level. II. Wear-Resistant and Durable, with Low Maintenance Costs To address high-wear conditions, key components of the equipment are cast from high-manganese steel alloy. with an integrated design of the rotor disc and hammer heads that enhances impact resistance by three times. The unique screenless bottom structure prevents material blockages,…

In fields such as sand and gravel aggregates, mining, and construction waste recycling, the impact crusher has become one of the core pieces of equipment due to its unique advantages. Its core principle involves using a high-speed rotating rotor to hurl materials against the impact plate or into a stone-on-stone crushing chamber, achieving efficient crushing and shaping. This design endows it with three significant advantages. Impact Crusher: The All-Round Pioneer in the Field of Efficient Crushing I. Superior Crushing Efficiency and High-Quality Finished Product Grain Shape The impact crusher employs the principles of “stone-on-stone” or “stone-on-iron,” where materials undergo high-frequency self-impact crushing within the chamber. This increases energy utilization by over 30% and enhances processing capacity by 40% compared to traditional equipment. Meanwhile, the crushed finished products are mostly cubic in shape, with a flakiness content below 10%, meeting the requirements of high-end concrete for aggregate grain shape and directly improving the structural strength of engineering projects. II. Strong Adaptability and Low Maintenance Costs This equipment can handle various materials with a hardness of ≤350 MPa, ranging from limestone to basalt. Its modular design facilitates easy replacement of wear parts, with key components such as hammers and impact plates made…

As an important piece of equipment in industries such as mining, building materials, and chemicals, the double toothed roll crusher plays an irreplaceable role in the material crushing process thanks to its unique structure and working principle. Its core components—two oppositely rotating toothed rolls—achieve efficient crushing by subjecting materials to a combined action of shearing, squeezing, and splitting through their sharp teeth on the surface. Double Toothed Roll Crusher: A “Versatile Player” in the Field of Material Crushing This equipment offers significant advantages: Firstly, it demonstrates strong adaptability, capable of processing medium- to low-hardness materials such as coal, limestone, shale, and coke, and is particularly adept at crushing cohesive materials with high moisture content, effectively preventing blockages. Secondly, its crushing ratio is adjustable; by modifying the gap between the toothed rolls or their rotational speed, the particle size of the output material can be precisely controlled to meet various process requirements. Additionally, it consumes low energy and generates minimal noise. The direct engagement of the toothed rolls for crushing reduces energy loss in intermediate steps, while its enclosed structure minimizes dust emissions, aligning with green production standards. In the coal industry, the double-toothed roll crusher can crush raw coal to…

The double-stage crusher is an innovative crushing equipment designed for medium. And low-hardness materials, widely used in fields such as mining, building materials, and chemical industries. Its core advantage lies in its double-stage crushing structure—materials are successively struck by high-speed rotating hammers on the upper and lower rotors. Enabling a continuous operation mode of “single feeding and double crushing.” This design not only significantly enhances crushing efficiency but also refines materials into more uniform particle sizes. Reducing the burden on subsequent screening processes. Double Stage Crusher: A Revolutionary Tool for Efficient Crushing Compared to traditional single-stage crushers, the double-stage crusher boasts three prominent features: Firstly, its discharge particle size is adjustable, allowing it to easily meet various process requirements by modifying the gap between the hammers and the liner plate. Secondly, its wear-resistant components are made of high-chromium alloy, extending their service life by 2-3 times and reducing maintenance costs. Thirdly, its screenless bottom design effectively prevents clogging from wet materials, making it particularly suitable for processing cohesive materials with high moisture content. Against the backdrop of increasingly stringent environmental requirements. The double stage crusher achieves low dust and low noise operation through optimized sealing structures and noise reduction designs….

Huashengming as a roll crusher manufacturer for sale pays great attention to user experience and service quality, and user-centred is our business philosophy. We offer various models of roll sand making machine to meet the needs of different users. In addition to high quality products, we also attach great importance to after-sales service. We have established a perfect after-sales service system to provide users with a full range of technical support and solutions. In the mining, building materials, metallurgy industries, large crushing equipment is the ‘main bearer’. And in this kind of equipment, the role of the roller machine is not small. Huasheng Ming roll machine can stand out in many brands, become the ideal choice for more and more users, it is strong in what? 1. High crushing efficiency, doubling production capacity is not a dream Huasheng Ming adopts double-roller high-pressure crushing design, with the transmission system, can easily cope with limestone, coal gangue, shale and other materials crushing. Compared with the traditional equipment, the output is increased, but the energy consumption is lower! 2. Excellent material, durability is the hard truth! As many bosses know, crushing equipment is afraid of ‘can’t take it’ and ‘wear fast’. Huashengming roller…

In large-scale industrial scenarios such as mining, building material production. And resource recycling, the large double roll crusher has become the core equipment for medium. And fine crushing operations, thanks to its efficient, stable, and controllable characteristics. Its core working principle involves applying squeezing, shearing. And grinding forces to materials through two high-strength rollers rotating towards each other, enabling continuous material crushing. The gap between the rollers can be precisely adjusted. With the discharge particle size ranging from 0.5 to 30 millimeters, meeting diverse needs from coarse to fine crushing. Large Double Roll Crusher: A Pillar in the Industrial Crushing Field This equipment offers significant advantages: it features a high-wear-resistant alloy roller surface. With a single processing capacity exceeding 100 tons per hour, suitable for medium- to high-hardness materials such as limestone, granite, and iron ore. The hydraulic system supports dynamic adjustment of the roller spacing. And when combined with an intelligent control system, it can optimize crushing parameters in real time. Ensuring uniform particle size of the finished products. Its modular design facilitates easy maintenance. Extending the replacement cycle of key components such as roller skins and bearings to over one year, and reducing overall operating costs by 30%. Large Double Roll Crusher have been…

As a core piece of equipment in the field of industrial crushing, the double-stage crusher has become an ideal choice for processing medium-hard materials such as coal gangue, shale, and furnace slag, thanks to its unique design and high-efficiency performance. It innovatively employs a double-stage rotor structure. After materials are coarsely crushed by the upper-stage rotor. They immediately enter the lower-stage rotor for secondary fine crushing, forming a composite crushing mode of “hammering + impacting.” This design not only reduces energy consumption by over 30% compared to traditional single-stage crushers but also improves the uniformity of the discharge particle size by 50%, directly meeting the stringent requirements for raw material particle sizes in industries such as building materials and chemicals. Double-Stage Crusher: An Innovative Tool in the Realm of High-Efficiency Crushing During operation, the powerful shearing force generated by the synchronous counter-rotation of the double-stage rotors can easily crush wet materials with a moisture content of up to 25%, effectively addressing the industry pain points of material blockage and wall adhesion commonly encountered with traditional crushers. Meanwhile, the screenless bottom design eliminates the need for pre-drying treatment of materials, significantly enhancing adaptability. In terms of environmental protection, the fully enclosed…

The double-toothed roller crusher is a medium and fine crushing equipment widely used in industries such as mining, metallurgy, chemical engineering, and building materials. And is highly favored for its characteristics of high efficiency, energy conservation, and simple structure. Its core structure consists of two parallel-mounted toothed rollers. Driven by motors, these toothed rollers rotate towards each other, utilizing the teeth on their surfaces to shear, squeeze, and split materials, thereby achieving material crushing. Compared to traditional crushers, the double-toothed roller crusher offers advantages such as uniform discharge particle size. And a low over-crushing rate, making it particularly suitable for crushing medium-hard. And soft materials, such as coal, limestone, and shale. Double-Toothed Roller Crusher: An Efficient Industrial Tool for Crushing This equipment is flexible in operation, allowing for the control of discharge particle size by adjusting the spacing between the toothed rollers to meet different production requirements. Its modular design facilitates easy maintenance. And the toothed rollers can be quickly replaced upon wear, significantly reducing downtime. Additionally, the equipment employs a sealed structure that effectively minimizes dust emissions, meeting environmental protection standards. In scenarios such as coal washing and building material preparation, its stable operation and low energy consumption characteristics…

The impact crusher, also known as a sand-making machine. Is a widely used crushing equipment in fields such as mining, building materials, and transportation. It operates on the principles of “stone-on-stone” or “stone-on-iron,” utilizing a high-speed rotating rotor to hurl materials into the crushing chamber. Where they collide violently with the impact plate or a layer of materials, achieving fine crushing and shaping of the materials. This process is not only highly efficient. But also results in uniformly shaped finished products with a low content of needle-like and flaky particles. Making it particularly suitable for producing high-quality manufactured sand. Impact Crusher: A Powerful Tool for Efficient Sand Making This equipment boasts significant advantages: Firstly, its compact structure occupies a small footprint, facilitating easy installation and maintenance. Secondly, it features a deep-cavity rotor design that enables a large processing capacity, reducing energy consumption by over 20% compared to traditional equipment. Thirdly, its wear-resistant parts are made of high-chromium alloy, extending their service life by 30% and significantly lowering operational costs. Additionally, by adjusting the rotor speed and the gap between the impact plates. The output particle size can be flexibly controlled to meet different process requirements. In the current context of…

In numerous industrial sectors such as mining, coal, and building materials. The double-toothed roll crusher has become a key piece of equipment in the material crushing process owing to its unique advantages. Double-Toothed Roll Crusher: A Capable Assistant for Efficient Crushing The equipment primarily consists of two relatively rotating toothed rolls. Which are equipped with sturdy and durable crushing teeth. When materials enter the crushing chamber, they are subjected to the intense squeezing. And shearing forces of the two toothed rolls, and are rapidly crushed into smaller pieces. This crushing method not only efficiently handles large chunks of material but also precisely controls the discharge particle size. Meeting the stringent requirements of different production processes for material granularity. Its structural design is compact and reasonable, occupying a small area and saving valuable production space. Moreover, the equipment operates stably and reliably. And its worn-out components can be easily replaced, significantly reducing maintenance costs and time while enhancing production efficiency. In terms of environmental protection, the double-toothed roll crusher also excels. It operates with low noise and minimal dust, effectively reducing environmental pollution and aligning with the concept of green development in modern industry. With the continuous advancement of technology, the…

+86-18703839693

+86-18703839693