Achieving peak performance from your granite sand making machine begins long before material reaches it. The key to optimization lies in superior feed preparation. Integrating a roller crusher as a dedicated secondary crushing stage is the most effective strategy. This machine pre-processes primary-crushed granite, transforming it into an ideal feedstock that allows your sand maker to operate at maximum efficiency. A roller crusher excels in this role by applying controlled compressive force. It breaks down the hard, abrasive granite into a more uniform, cubical product with a significantly reduced percentage of pre-existing fine dust. By feeding this optimized material to your sand making machine, you solve major performance constraints. The sand maker’s components experience less abrasive wear, its crushing chamber maintains better rock-on-rock action, and energy is used for final shaping rather than initial size reduction. This leads directly to higher sand output, improved product shape, and lower operating costs per ton, fully unlocking your sand making machine’s designed potential. Ready to maximize your granite sand plant’s return on investment? Contact us to learn how a roller crusher system can be your first step toward optimal performance.

As a key part of construction and mining, stone crushing is often seen as profitable. But with market fluctuations, strict regulations, and rising costs—Is it still profitable in 2025? Here’s a simplified analysis. Core Truth: Profit Exists, But Isn’t Guaranteed Strong demand from infrastructure and urban renewal supports the industry. The global crusher market is set to hit $49B by 2028 (CAGR 4.3%). US operations often have 20-35% EBITDA margins. Profitability varies by region and strategy. Oversupply in some markets cuts margins (e.g., 30% price drops in parts of China). Success depends on cost control, compliance, and demand capture. Key Profit Drivers 1. Market Demand & Pricing Booming infrastructure (India, SE Asia) boosts demand and prices. Oversupply (parts of China) causes price wars. US benefits from infrastructure bills; Europe from high waste recycling rates. 2. Cost Control (Make-or-Break) Major costs: – Equipment: Energy-efficient crushers (e.g., double roll) cut long-term costs. – Raw Materials/Mining Rights: Low-cost access boosts competitiveness. – Ops & Enviro: Dust/noise control is mandatory—poor management kills profits. 3. Policy & Compliance Non-compliance leads to fines/shutdowns. Green practices (e.g., waste recycling) may get subsidies, boosting profits. 2026 Profit-Boosting Tips Right Equipment: Choose energy-efficient, low-maintenance models (e.g., double roll) or…

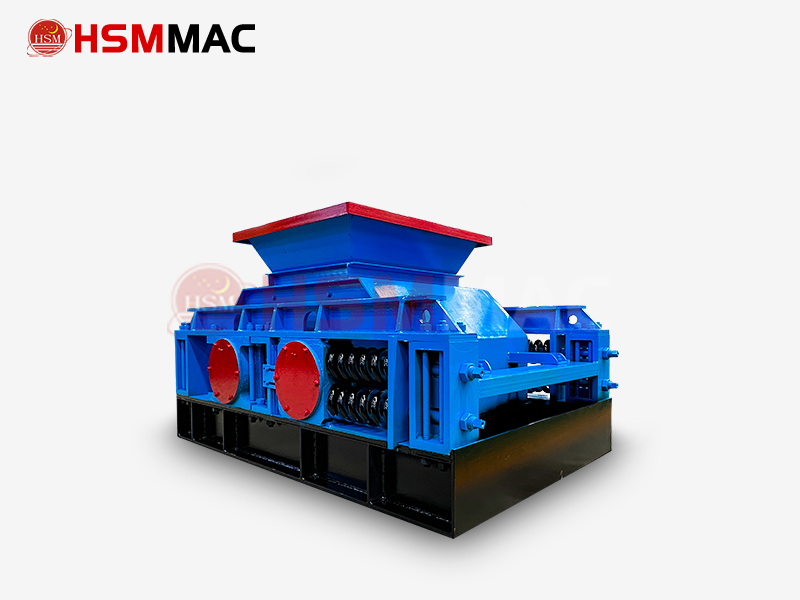

The working principle of a roll crusher centers on controlled compression between two counter-rotating rolls, delivering several distinct operational benefits. As materials pass through the adjustable gap between the rolls, they undergo gradual size reduction rather than sudden impact, resulting in superior product quality and system efficiency. Operational Advantages Through Design: Controlled Compression – Gradual crushing minimizes fines production Adjustable Gap System – Precise control over final product size Even Wear Distribution – Prolongs equipment service life Energy Efficient Operation – Lower power consumption per ton processed Versatile Material Handling – Effective for both dry and slightly moist materials This efficient working mechanism makes roll crushers particularly valuable in mineral processing, aggregate production, and industrial applications where product consistency matters. Ready to optimize your crushing process? Contact Huashengming Heavy Industry in Zhengzhou to explore how our roll crushers can improve your operational efficiency and product quality.

When determining the best crusher for your concrete recycling operation, long-term operating costs and final product value are key. The Roller Crusher provides a compelling advantage through its efficient, low-wear design. Its compression-based crushing mechanism consumes less energy per ton than impact-based alternatives, directly reducing your power costs. Furthermore, the roller crusher’s ability to produce a consistent, in-spec product with fewer fines means more saleable material and less waste. With fewer high-speed wear parts compared to impact crushers, maintenance is simpler and less frequent, leading to lower downtime and reduced parts expenditure. For operations focused on turning concrete demolition into a profitable aggregate product, the roller crusher offers an optimal balance of performance and economy. Lower your cost per ton of recycled concrete. Discuss your project with Huashengming’s experts and discover how our Roller Crusher technology can enhance your bottom line.

A roller crusher achieves size reduction through mechanical compression between two counter-rotating cylinders, operating at controlled speeds typically ranging from 50 to 300 RPM. This method delivers distinct advantages over impact crushing, including lower energy consumption, reduced dust emissions, and more consistent particle shape. The adjustable gap mechanism allows operators to fine-tune output size with precision, while robust construction ensures durability in demanding environments. Key Technical Advantages: Adjustable Compression Settings – For exact product sizing control Minimal Fines Production – Optimizes yield and reduces waste Energy-Efficient Design – Lowers operational costs per ton Low Maintenance Requirements – Simplified design enhances reliability Interested in optimizing your crushing circuit? Connect with our technical team to discuss how a Huashengming roller crusher can be integrated into your specific operation for maximum efficiency and cost savings.

The unique properties of lithium ores, such as spodumene and lepidolite, demand a precise and selective crushing approach to preserve valuable mineral crystals and maximize recovery rates. Huashengming’s Roller Crusher is ideally suited for this task, serving as a key preparatory stage before further milling and beneficiation. Unlike impact crushers that generate excessive fines through violent fragmentation, the Roller Crusher employs a controlled compressive force. This method applies gradual pressure, promoting inter-particle crushing that naturally cleaves the ore along grain boundaries. This results in more uniform particles with minimized over-crushing, effectively liberating lithium-bearing minerals while reducing the generation of slimes that can hinder downstream flotation or chemical processing. It ensures the feed material for subsequent stages is optimally sized, protecting both equipment efficiency and final product yield. Optimize your lithium ore liberation process. Contact us to discuss integrating a Roller Crusher into your circuit.

Sand and gravel are widely used in construction, transportation and water conservancy. But are they natural raw materials or man-made products? The answer depends on their sources and processing methods. Natural Sand and Gravel: Nature’s Gifts Natural sand and gravel are typical natural raw materials, formed by long-term natural forces like weathering, erosion, transportation and deposition of surface rocks. Sand comes mainly from rivers, lakes and seas (sea sand needs desalination for construction due to high salt content). Gravel, often found in mountains and river valleys, forms via geological movements or glacial impact, requiring only simple screening before use. Long a top choice for construction due to wide sources and low costs, over-exploitation of natural sand and gravel has caused ecological issues like riverbed collapse and soil erosion. Many countries have restricted its mining, boosting the development of man-made alternatives. Man-Made Sand and Gravel: Human Ingenuity Man-made (or machine-made) sand and gravel are typical man-made products, processed by crushing, screening and shaping natural rocks via professional machinery. With standardized production processes, they boast controllable particle size, stable quality and customizable gradation, effectively compensating for the shortage of natural sand and gravel. They can also use industrial solid wastes like construction…

When it comes to crushing pebbles efficiently, the hydraulic double roll crusher stands out as a reliable choice. But what exactly is it, and why is it favored for pebble processing? Core Function As a specialized pebble crusher, it’s designed to break down hard, smooth pebbles into smaller, usable aggregates. Unlike some crushers that rely on impact or pressure alone, its “double roll” design paired with hydraulic control makes it gentle yet powerful for pebble material. How It Works Two rotating rolls (the core component) are driven by a motor. When pebbles enter the crushing chamber, the hydraulic system adjusts the gap between the rolls to control the output size. The rolls squeeze and grind the pebbles until they meet the desired particle size, then discharge them smoothly. Key Advantages for Pebbles Low Wear: The rolls’ surface (often made of wear-resistant alloy) handles pebbles’ smooth, hard texture without frequent replacement. Controllable Output: Hydraulic adjustment lets you easily tweak the final aggregate size, fitting needs from construction sand to small gravel. Energy Efficiency: It uses less power compared to impact crushers, saving costs for long-term pebble processing. Common Uses You’ll find it in projects like road construction (producing base aggregates),…

As a standout basalt sand making machine, the Roller Crusher excels in processing high-hardness basalt (Mohs hardness 6-7). It directly addresses traditional sand-making pain points like low efficiency, poor particle shape and high costs, making it the top choice for basalt sand production lines. Below are its core advantages: 1. Strong Wear Resistance: Built for Basalt’s Hardness This basalt sand making machine adopts HRC60+ high-chromium alloy or wear-resistant welded roller surfaces, tailored for basalt’s wear resistance. The roller replacement cycle reaches 1 year (30% longer than ordinary equipment). Its “double-roller extrusion + shear” principle avoids violent material impact, reducing vulnerable part wear and solving frequent replacement issues of traditional machines. 2. High-Quality Sand: Meets High-End Demands Extrusion crushing avoids over-crushing, producing sand with ≥90% cube particles and ≤5% powder content—fully meeting high-end requirements for concrete aggregates and road bases. With 0-50mm stepless adjustable discharge size, it flexibly produces coarse, medium and fine sand, a key edge of this basalt sand making machine. 3. Energy-Saving & Cost-Effective: Lighten Operational Burden Compared with other basalt sand making machines, it has ultra-low unit energy consumption (5-8kWh/ton), saving 25% more energy than Jaw Crushers and 18% than Impact Crushers. Its compact structure takes only…

As a professional aggregate and marble sand making machine, the roller crusher is the top pick for crushing and sand making. Its tailored design and core tech fix key industry pain points—here’s why customers choose it fast: 1. Crushes Hard Materials (Marble/Aggregate) Durably? Yes! 2. Makes High-Quality Sand That Sells for More? Only It Does! Customers care most about sand value. This aggregate and marble sand making machine makes marble sand with 95% whiteness and ≤3% powder. Aggregate sand has cubic grains and even gradation—no re-screening needed for concrete or decor. Adjust output (0-5mm) with a twist to fit any job. 3. Cuts Energy Costs—Great for Small Plants? Save Big! Traditional crushers use 8-10kWh per ton; this aggregate and marble sand making machine uses just 5kWh. Process 100,000 tons/year? Save $30k+ on electricity. It’s 60% less powerful than old models, fits 3-5㎡, and one person can run it. Labor, space, and energy costs drop 30%—perfect for tight budgets. 4. Works in Cities Without Breaking Rules? It’s Eco-Friendly! Inspectors crack down on pollution. This aggregate and marble sand making machine has a closed chamber + dust filter: dust stays under 10mg/m³, noise under 75dB (way below standards). No loud impacts or dust—use it near cities…

Aggregate sand making machine is core equipment for high-quality artificial sand, and it’s indispensable in construction and infrastructure. With natural sand shortage and stricter environmental policies, here’s why it’s favored. Core Reasons for Using It Solve Natural Sand Shortage Over-mining depletes natural sand (many regions ban/restrict its exploitation). The machine turns limestone, granite, river pebbles into high-quality artificial sand, filling the supply gap. Stable Product Quality Unlike uneven, impure natural sand, it controls finished sand’s particle shape, gradation, and fineness modulus via parameter adjustment. The artificial sand is uniform (mostly cubic), adheres well to cement, and boosts concrete/mortar strength. Cost-Effective & Eco-Friendly Cost: Raw materials (waste rock, construction waste) are cheap and easy to get, cutting sand procurement costs vs. long-distance natural sand transport. Eco: It recycles waste (e.g., crushes construction waste into sand), reduces solid pollution, and meets environmental policies. Strong Scenario Adaptability It’s customizable for different raw materials (hardness, moisture) and production needs (capacity, particle size), fitting small construction sites or large production lines. Key Application Scenarios Construction: Concrete aggregate for high-rises, bridges, roads. Infrastructure: Qualified sand for railways, highways, water conservancy projects. Building Materials: Matches cement/brick factories for auxiliary materials. Simple Selection Tips Raw Material Hardness: Choose…

Lead zinc crusher(also known as double-roll crushers) Huashengming Double Roll Crusher has become the ideal choice for lead-zinc ore crushing due to its precise particle size control, wear-resistant and corrosion-resistant design, energy-efficient performance, and intelligent control. Whether improving ore recovery rates, reducing operational costs, or tackling complex working conditions, Huashengming Double Roll Crusher delivers substantial economic and social benefits for lead-zinc mining enterprises. 1.Working Principle The Huashengming double-roll crusher crushes materials by applying continuous compressive force through two counter-rotating rolls. This relatively “gentle” crushing method offers key advantages for lead-zinc ore processing. 2. Advantages Precise particle size control effectively reduces over-crushing Lead-zinc ores are predominantly sulfide minerals. Excessive impact crushing generates significant powder, leading to metal loss during beneficiation. The slow compression of double-roll crushers effectively minimizes the production of excessively fine powder, ensuring uniform particle size distribution in the final product. This is crucial for enhancing mineral recovery rates. Specialized Wear-Resistant and Corrosion-Resistant Design Addressing the corrosive nature of sulfur-containing lead-zinc ores, Huashengming’s double-roll crushers feature roll surfaces made of high-chromium alloy (hardness up to HRC 60-62) with anti-corrosion coating. This design extends roll surface lifespan to 6-8 months under harsh operating conditions. Energy-Efficient Operation Reduces Overall Costs The…

+86-18703839693

+86-18703839693