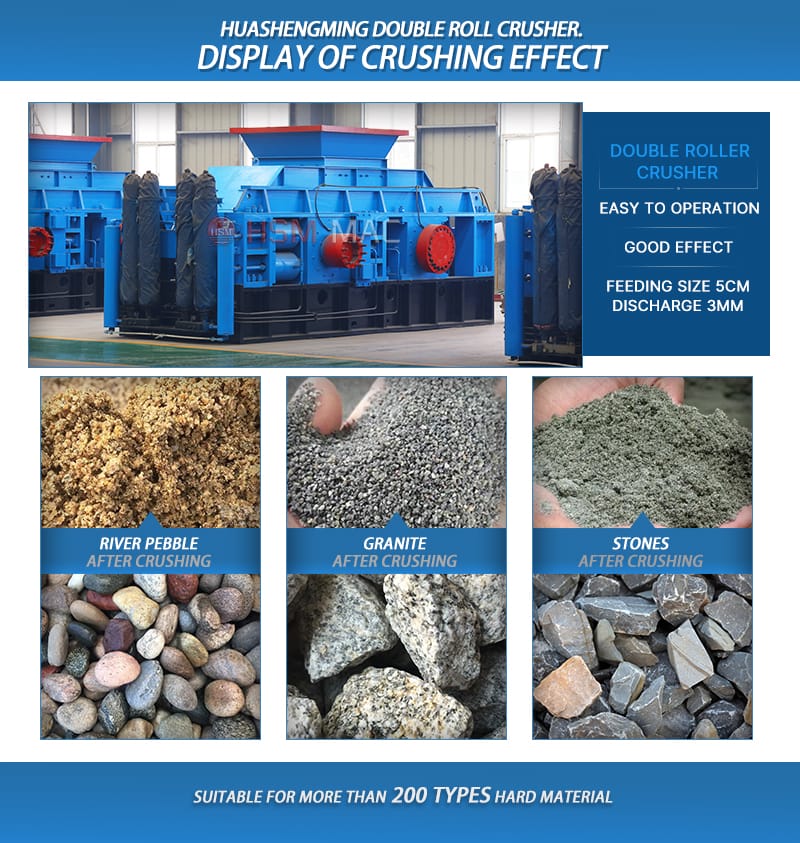

Applicable materials:Coal, Coal gangue, cement, silicate, River pebbles, calcite, quartz, glass, marble, pebbles, bentonite, iron ore, lapis lazuli, mountain stone, limestone, weathered sand, pyroxene, granite, basalt, etc.

Application scope: Highway, railway, high-rise buildings, municipal, hydropower dam construction, concrete mixing station, sand and stone field, etc.

Due to the prohibition of natural sand mining, as well as the need for a large amount of sand and gravel for housing construction and highway construction, and the controllable particle size and full specifications of machine made sand, the machine made sand market has good sales and large profit margins.

Quartz stone sand making machine has achieved a breakthrough in the equipment manufacture of aggregate production. Quartz stone sand making machine ,also named as double roller crusher or roller sand making machine, runs by driving two motors and two pairs of rollers to grind the material fed. Double roller crusher can operate crushing material less than 80mm as well as the finished product size 50 mesh-20mm.

2.The finished product features pretty shape, well gradation, low over-crushing rate and high output.

4.Roller skin contains high content of chromium, manganese and other rare metal materials. Adjustable discharge size.

It is suitable for crushing sticky stone material into medium size. Roller crusher utilizes two rollers rotating in opposite direction to crush the material, which consists of motor, bracket, fixed rollers, movable rollers and springs. Most of its roller surfaces are glossy, and the bearings of the movable rollers can be moved along the machine frame and held against it by springs. Therefore, When a particularly hard object accidentally drops into the machine, the bearing can be moved out of the way to expel it. Furthermore, before the machine runs, the gap between the two rolls should be adjusted with shims to ensure the crushing size.

The quartz stone sand making machine operates through rollers. The pebbles, put into the machine through the inlet, are crushed by the squeezing between the rollers. The discharge size can be controlled by adjusting the gap between the two rollers. If the gap becomes larger, the discharged size becomes larger. While the gap becomes smaller by compressing spring, the discharge size also becomes smaller.

Quartz stone sand making machine is divided into several kinds: Spring fine crushing sand making machine, cardan shaft drive fine crushing sand making machine, hydraulic fine crushing sand making machine.

You can choose the machine according to your budget and the facts.

There are small, medium and large fine crushing sand making machine.

Production capacity: 2-12 tph

Production capacity: 20-50 tph

Large fine crushing sand making machine: 1200×800,1200×1000,1500×800,1500×1000,1500×1200,1800×1200,2000×1000 or larger.

Production capacity: 50-400 tph

HSM machines features different configurations. The sales manager can recommend the proper product to the customers according to their facts.

+86-18339818180

+86-18339818180