The double tooth roller crusher consists of two counter-rotating toothed rolls. The material enters the crushing chamber through the feed inlet and is crushed by the interaction of the toothed rolls. The crushed material is discharged through the discharge outlet, completing the crushing process.

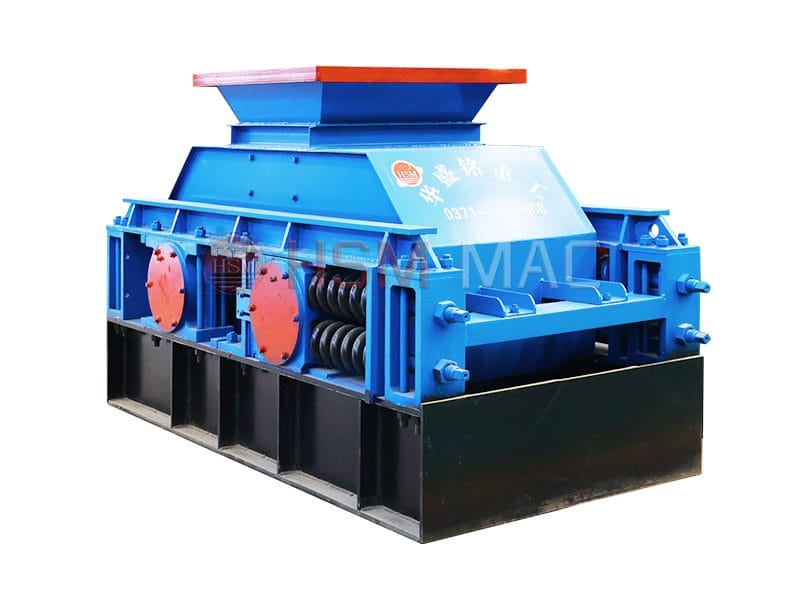

The double tooth roller crusher is mainly composed of the following parts

Body: The base and support structure of the crusher, including the feed inlet and discharge outlet.

Toothed Rolls: Rolls with a serrated working surface that rotate in opposite directions to crush the material.

Transmission Device: Transmits the power from the electric motor to the toothed rolls, causing them to rotate.

Control System: Controls the start/stop of the crusher, adjusts the crushing effect, and monitors the operating status of the equipment.

Operating Procedure:

Place the material into the crushing chamber through the feed inlet.

Start the crusher, and the toothed rolls begin to rotate, crushing the material.

Discharge the crushed material through the discharge outlet.

Adjust the crushing effect of the crusher as needed, such as adjusting the spacing and speed of the toothed rolls.

Stop the crusher when the material reaches the specified fineness or if the equipment malfunctions.

The double tooth roller crusher is widely used in industries such as coal, mining, and metallurgy, capable of crushing materials of various hardness levels. Additionally, depending on different process requirements, the double-toothed roll crusher can perform coarse crushing, medium crushing, and fine crushing, among other crushing methods.